Golding press information

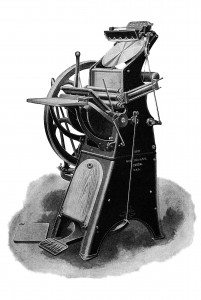

The Golding Official line of presses is large. They come in eleven different models from the 2 x 3 Junior to the 10 x 15 No. 7 tabletop. In addition to those tabletops, Golding also made two sizes of a treadle operated floor model called the Rotary. Even more unusual is the Golding Imprinter which was a large stationary platen tabletop with a flywheel. The more traditional tabletop versions are very popular today, and are among the best quality available. The engineering principal and design is superior to many presses on the market and was so successfully copied by Sigwalt that it is often confusing to identify if not very familiar with the two manufacturers. The most popular and available of all the models are the No. 3 (5 x 8) and the No. 4 (6 x 9).

Stationary platen No. 9

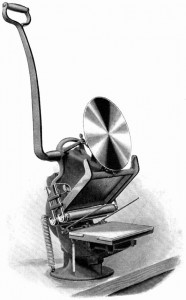

The Official Map (stationary platen) line is unique to Golding. Instead of the platen moving up to meet the bed, the opposite occurs when you pull the handle. The bed travels down to meet the platen. It is also known as a map press. These presses were made for the purpose of printing the corner blocks on large sheets of paper like maps or blueprints. These models are more difficult to find but well suited to modern printing using plates or the boxcar system. Not recommended for hand set type enthusiasts as your lockup has to be perfect or it will fall out as the bed and chase moves down to meet the platen.

PearlThe Old Style Pearl is considered one of the most beautiful presses ever produced. It was originally a tabletop that could be ordered in several configurations. The most popular being ordered with a metal base with drawers, flywheel, and treadle. This is the configuration found most often today. It could also be operated as a floor press with the wooden shipping crate it came in if you could not afford the metal base. The tabletop versions are not commonly found, but, are wonderful presses to own should you be lucky enough to find one.

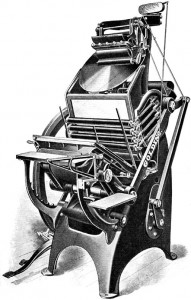

Improved PearlThe Improved Pearl was designed to be a floor press from the start. It added a third roller and throw off which really does improve the printing experience. It increased in weight over the Old Style, but, it still can be partially disassembled which makes moving it easier than a traditional floor model like the Jobber. It was a very successful upgrade and remains very popular today. Golding made three Improved Pearl models.

JobberThe Jobber line was the professional model line. These are all floor presses with more features than found on the Pearls. They also have more impression strength and better inking. The Jobber No. 6 is about the same size as the Pearl No. 11 buts weighs several hundred pounds more. All Jobbers have one piece body castings which keeps them aligned even on an uneven floor. The two most commonly found are the No. 6 (8 x 12) and the No. 7 (10 x 15). Once in the printers possession, they are prized and don’t often come back up for sale. They are particularly beautiful when equipped with all the accessories. Both smaller sizes are easy to treadle.

Art Series JobberThe Art Series Jobbers are serious, massive hand fed presses. They are like a traditional Jobber on steroids as all castings are increased in size and weight. All Art Series Jobbers must be motor driven as they are too big to comfortably operate by treadle. Later models had four rollers, duplex inking, adjustable rails and all the other Jobber features. Full length fountains had the ability to be divided for printing multiple colors at the same time. You can easily print two full 8.5 x 11 sheets simultaneously or die cut most anything desired. The “small” one weighs 2600 lbs.!

To my knowledge, this is the most complete list available online of Golding models,

with chase sizes, and important clarifying notes.

How to determine what model you have.

Press size is determined by measuring the dimensions inside the chase. This can vary slightly as most original chases were cast iron but steel versions will commonly be found made by others as well. The steel versions would typically have slightly larger inside dimensions because the stronger material allowed for the chase to have thinner sides.

When in the process of determining what model you have, never go by just one factor. Golding was constantly changing and upgrading all the lines so it you may find an unexpected feature that tends to throw you off. A good example is the Old Style Pearl No. 3. You can see images and information all over the web, that show and say that it has two drawers and the No. 1 has three as an identifying feature. We now know that early No. 3’s also had three drawers and it changed to only two at some point in the manufacturing. It is still unmistakably a No. 3, however, as the chase size is clearly 7 x 11. To add to the confusion, there are some look a likes that were produced by other manufacturers. Sigwalt has already been mentioned. He made a very good copy of the Official known as the Nonpareil. Craftsmen Machinery Co. made a good copy of the Improved Pearl known as the CMC Jobber. There were copies of the Old Style Pearl and the Jobber made by other firms in Great Britain as well. In most cases we know of however, Golding identified his presses by putting his name or model on them somewhere. The only exceptions seem to be very late production examples. He was also very good at putting a serial number at the top of the bed just below the ink disk. Be careful when looking for serial numbers as there are both part numbers cast into parts and assembly numbers sometimes stamped into parts. Assembly numbers were used to keep custom machined parts with the correct press during manufacturing. Part numbers just identified which part it was. This brings up another interesting note. If replacing a part on a early press, you may have some fit issues even when replacing with the same part from another press of the same model. Parts were not always mass produced and so accurate they can be interchanged between all presses without some alteration. This is why assembly numbers were stamped into parts. This mostly occurred during the early years of production. Golding was also always upgrading and changing designs of many parts. An ink disk support arm from a 1879 press may not fit a press built in 1890 at all.

Reference material:

A Brief History of Golding and Co. by Stephen O. Saxe

Golding Official Manual

Golding Pearl Catalog

Golding Pearl Oldstyle No. 1 and 3 diagram and parts list

Golding Improved Pearl parts diagram

Golding Jobber parts diagram

Golding Jobber parts list for diagram

Golding patent documents

Now Available!New faithfully reproduced Golding catalog from 1900. Filled with information about the Golding & Co. presses and other printing equipment available in the era. Printed on high quality 70lb. text with 120lb. cover. Over 100 pages of interesting information. A valuable resource for Golding owners. Makes a great gift for the letterpress enthusiast! Price: $34.95 which includes shipping. Click here to purchase.

|

|